Vibration Sensors for Industrial Fans

AirVibe Sensor for Monitoring Industrial Fans

The AirVibe vibration analysis and monitoring sensor represent a significant advancement in industrial fan monitoring. This report outlines the financial and technical benefits of implementing the AirVibe sensor for industrial fans and fans vibration analysis, addressing its unique features and capabilities.

Technical Considerations

- Long-Range Wireless Connectivity: AirVibe’s utilization of the LoRaWAN Protocol allows for long-range data transmission, up to 10 miles with line of sight and 1 mile without. This is particularly advantageous for fan vibration monitoring located in remote or difficult-to-access areas.

- Enhanced Battery Life: By removing the battery from the heat of the machine and using a low-power protocol, AirVibe boasts an impressive 4+ year battery lifecycle. This reduces the frequency of maintenance interventions for battery replacement.

- Continuous Data Transmission: The ability to continuously transmit overall data is crucial for real-time monitoring of industrial fans, enabling immediate detection of anomalies and potential failures.

- Integration with Existing TriVibe Technology: Leveraging the existing TriVibe technology with an extension for the LoRaWAN module ensures high-resolution data analysis and customizable output, beneficial for detailed fans vibration analysis.

Financial Considerations

- Reduction in Unscheduled Downtime: Continuous and real-time monitoring of fans can significantly reduce unscheduled downtime by enabling predictive maintenance, leading to substantial cost savings.

- Long-Term Operational Savings: The extended battery life and reduced need for frequent maintenance visits contribute to significant long-term operational savings.

- Cost-Efficiency in Remote Monitoring: The long-range wireless capability eliminates the need for extensive wiring or complex installation processes, especially in remote locations, thereby reducing initial setup costs.

- Prevention of Catastrophic Failures: Early detection of potential issues can prevent catastrophic failures, which can be extremely costly in terms of repairs, replacements, and operational downtime.

Conclusion

The AirVibe sensor, with its advanced technical features such as long-range wireless connectivity, enhanced battery life, and continuous data transmission, offers a highly effective solution for monitoring industrial fans. Financially, the sensor presents a cost-effective option with its potential to significantly reduce maintenance costs and prevent expensive unplanned downtimes and catastrophic failures. These advantages make the AirVibe sensor a prudent investment for industries seeking reliable, efficient, and cost-effective monitoring solutions for their industrial fans.

Trivibe Wireless Sensor for Monitoring Industrial Fans

In the realm of industrial maintenance, the monitoring of equipment like industrial fans is critical for ensuring operational efficiency and safety. The Trivibe Wireless Sensor offers a highly specialized and efficient solution for this purpose. This report presents a detailed analysis of why the Trivibe sensor is an exemplary choice for monitoring industrial fans.

The Trivibe sensor's ability to capture over 50,000 samples per second provides unparalleled high-resolution data. This high-resolution is crucial for detecting subtle changes in vibration patterns of industrial fans, which can be indicative of issues like imbalance, misalignment, or wear. Early detection of such problems through advanced ML/AI vibration visualization can lead to timely maintenance actions, preventing costly breakdowns.

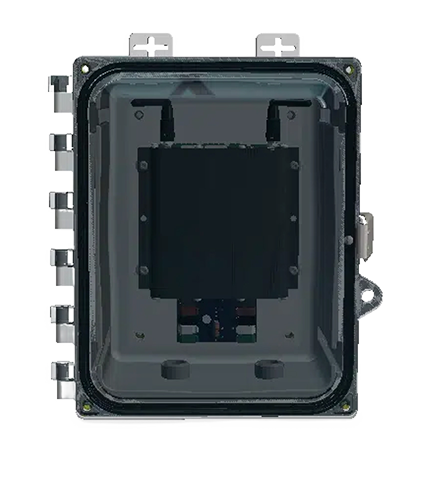

Dont want all the wires? Use an Airvibe and grab the data via Gateway with out Machine Gate.

This makes installation a breeze and the initial project cost less expensive.

The sensor's customizable dynamic data output with options such as high pass, low pass, and band pass filters allows for monitoring that is specifically tuned to the unique vibration characteristics of different industrial fans. Digital integration capabilities via the RS485 port make the sensor universally adaptable to various control systems. The availability of source code in Python on Jupyter Notebooks facilitates easy integration and programming, enhancing its applicability in diverse fan monitoring scenarios.

Manufactured in the USA, the Trivibe sensor is designed for quality and longevity, making it well-suited for the rigorous demands of industrial fan applications. The multiple mounting options and the ability to specifically design the sensor for particular fan applications underscore its versatility. The standard 1-year warranty, extendable to 5 years, and the sensor's ability to meet a high annual demand, signify its reliability and industry acceptance.

The sensor's broad frequency range (0.8 Hz to 6000 Hz) and temperature measurement capability via an internal RTD make it suitable for various types of industrial fans, including those in challenging environments. Its suitability for hazardous locations and its submersible feature, compliant with the IP68 waterproof standard, ensure reliable performance under diverse operational conditions.

The daisy-chaining capability of the Trivibe sensor reduces wiring complexity and installation costs, a significant advantage in large industrial setups with multiple fans. This feature, along with the sensor's long lifespan and minimal maintenance needs, contributes to its overall cost-effectiveness.

Conclusion

The Trivibe Wireless Sensor is a highly capable, adaptable, and robust tool for the monitoring of industrial fans. Its advanced data resolution, customizable features, durability, and versatility in application make it a standout choice for industrial environments. The ease of integration and cost-effective installation and maintenance further enhance its attractiveness as a monitoring solution. Therefore, it is strongly recommended for industries seeking to optimize the performance and maintenance of their industrial fans.

We can customize vibration solutions to fit your needs

Request For QuoteRecommended Products

- Airvibe and Machine Gate (Wireless installation on Roller element bearings)

- Trivibe (Continuous near real-time data on roller element bearings)

Why choose machine saver?

We are the fastest growing vibration technology company in the world

At Machine Saver, we have established ourselves as an industry leader in vibration monitoring through our relentless pursuit of excellence and innovation.

Contact Us